Precision Casting for Automotive Performance: Driving Innovation in Vehicle Engineering

The automotive industry stands at the intersection of mass production and extreme performance, where components must balance cost-efficiency with relentless durability. Precision casting has emerged as the manufacturing solution that delivers this dual advantage, enabling both everyday vehicles and high-performance machines to achieve new levels of reliability and efficiency. From compact electric vehicles to heavyweight trucks, the technology is quietly revolutionizing how cars are built.

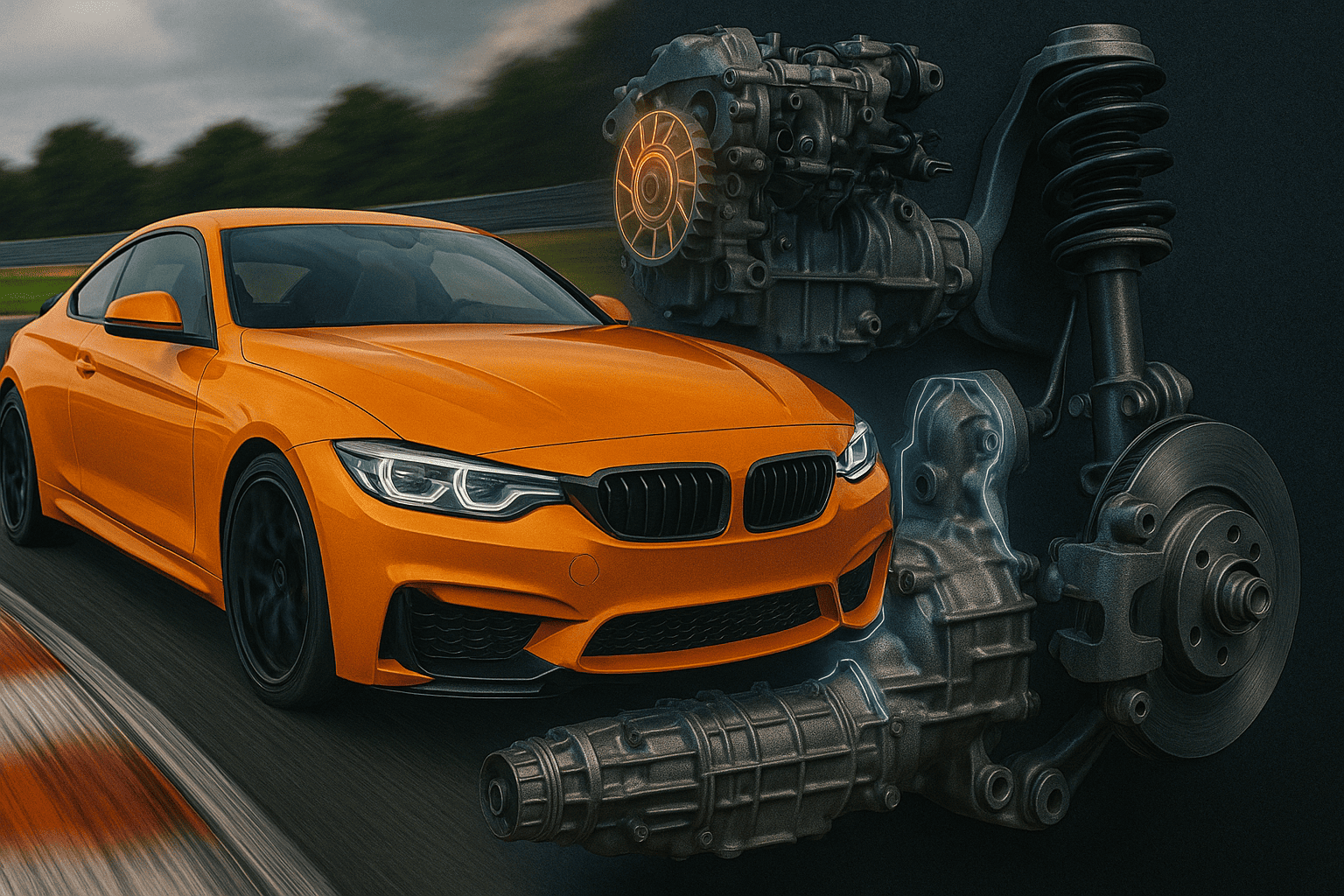

Modern vehicles present engineers with a complex matrix of challenges. Engine components face punishing thermal cycles, suspension parts endure millions of load cycles, and transmission elements must transfer increasing power densities. Traditional manufacturing methods often force compromises – stamped parts lack complexity, forgings limit design freedom, and assemblies create potential failure points. Precision casting overcomes these limitations by producing near-net-shape components with material properties precisely tuned to their function. The result is parts that are born perfect, requiring minimal machining and delivering optimized performance straight from the mold.

Material innovation drives much of casting’s automotive advantage. High-silicon aluminum alloys provide the ideal balance of lightness and strength for engine blocks. Nodular iron offers unmatched durability for differential cases. Most impressively, modern foundries can engineer varying properties within a single component – creating transmission housings with wear-resistant bearing surfaces and vibration-damping walls, all in one piece. This material magic happens through controlled solidification processes that would be impossible with conventional manufacturing. The aluminum alloy in a precision-cast cylinder head, for example, develops different crystalline structures in the combustion chamber versus the coolant passages, each optimized for its specific demands.

The geometric freedom of precision casting unlocks equally important benefits. Engine blocks can incorporate complex coolant jackets that keep temperatures even. Suspension knuckles achieve organic, weight-optimized shapes that outperform machined alternatives. Turbocharger housings combine multiple functions into single castings, reducing potential leak points. Recent advances in 3D printed sand cores have expanded these possibilities further, enabling internal features like helical oil passages or graduated wall thicknesses that follow stress lines. These aren’t just theoretical improvements – track testing shows cast suspension components lasting 3-5 times longer than forged alternatives under identical conditions.

The economic case for automotive precision castings grows stronger each year. Manufacturers report:

• 30-50% reduction in machining costs compared to billet alternatives

• 20-40% weight savings through optimized designs

• 15-25% improvement in component life cycles

These advantages scale across vehicle production, making precision casting a strategic advantage in an industry where pennies per part translate to millions in savings.

Looking ahead, the technology continues to evolve in ways that promise to redefine automotive design. Smart castings with embedded sensors will enable real-time component health monitoring. New aluminum-scandium alloys may further reduce weight while increasing strength. The integration of casting with additive manufacturing opens possibilities for cooling channels that follow heat gradients and reinforcement patterns that mirror stress flows.

For an industry undergoing its greatest transformation in a century, precision casting provides more than just parts – it offers the material solutions enabling next-generation vehicles. [Your Company Name] has been driving this automotive revolution, with our castings powering everything from urban EVs to championship-winning race cars. When performance, durability, and efficiency matter, automotive engineers increasingly turn to precision casting – not just as a production method, but as a competitive edge in an accelerating industry.