The Art and Science of Precision Casting: Where Durability Takes Shape

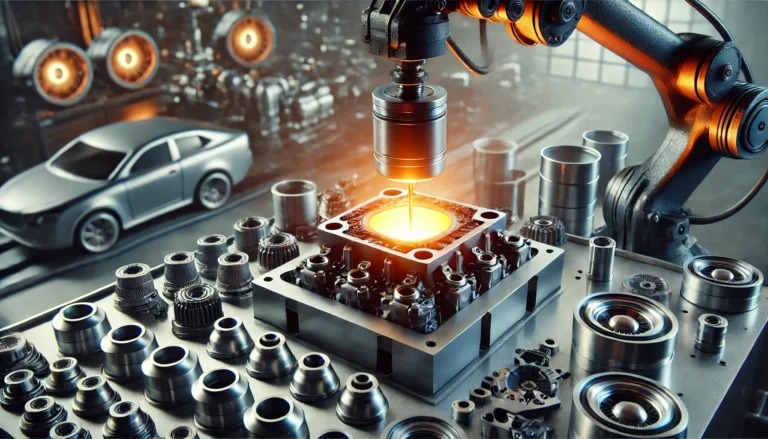

Ever wonder how the rugged bucket teeth on a mining excavator withstand crushing rock, day after day? Or how the critical components deep within heavy machinery endure relentless friction and impact? Often, the answer lies in the remarkable world of precision casting, also known as investment casting.

At Truecasteng, we live and breathe this intricate craft. We specialize in crafting high-performance wear parts and precision-cast components designed specifically for the toughest environments. Our mission? To deliver unmatched durability where it matters most.

Beyond Molten Metal: The Precision Casting Journey

Precision casting is far more than just pouring molten metal. It’s a meticulous blend of ancient technique and modern innovation. Here’s a glimpse into the magic:

- The Master Model: It all starts with an exact replica of the final part, typically crafted from wax or a 3D-printed polymer. This is the “master pattern.”

- Building the Shell: The master pattern is repeatedly dipped into a ceramic slurry and coated with fine refractory sand. Layer by layer, a robust ceramic shell is built around it.

- The Meltout: Once the ceramic shell is cured and hardened, the wax or polymer inside is melted or burned out in a high-temperature furnace. What remains is a hollow ceramic mold – a perfect negative cavity of the desired part.

- The Pour: Molten metal – often specialized alloys like high-chrome irons, manganese steels, or heat-resistant superalloys crucial for wear resistance – is carefully poured into the preheated ceramic mold.

- Breaking Free: After the metal solidifies and cools, the ceramic shell is broken away (often through vibration or water blasting), revealing the raw metal casting inside.

- Finishing Touches: Precision grinding, shot blasting, heat treatment (for enhanced properties), and rigorous quality inspection complete the process, ensuring the part meets exacting dimensional tolerances and performance standards.

Why Precision Casting? The Advantage for Wear Parts

For demanding applications involving abrasion, impact, and corrosion – the very definition of wear parts – precision casting offers unparalleled advantages:

- Complexity Without Compromise: Achieve intricate geometries, internal passages, and near-net shapes impossible with other methods like forging or machining. This allows for parts optimized for maximum wear life and functional efficiency.

- Exceptional Surface Finish: Parts emerge from the ceramic mold with a significantly smoother surface finish than sand castings, reducing the need for extensive machining and providing a better starting point for wear surfaces.

- Superior Metallurgical Integrity: The process allows for excellent control over the metal’s grain structure and properties. Combined with the right alloy selection, this delivers the durability and wear resistance essential for components in mining, construction, agriculture, and material handling.

- Material Versatility: Truecasteng leverages a wide range of ferrous and non-ferrous alloys specifically engineered for wear, heat resistance, and corrosion resistance, tailoring the solution to the exact operating environment.

Truecasteng: Your Global Partner for Durable Solutions

Based in [Your City/Region, e.g., China, a global manufacturing hub], Truecasteng combines decades of foundry expertise with cutting-edge technology. We understand the critical role our precision-cast wear parts play in your operations:

- Extended Component Life: Minimize costly downtime and replacement frequency.

- Optimized Performance: Parts designed for specific wear mechanisms maximize efficiency.

- Reliability Under Pressure: Components built to withstand the harshest conditions, ensuring operational continuity.

We proudly export our high-quality precision casting products directly to partners across North America, including the United States and Mexico, providing reliable supply chains and consistent performance for industries where durability is non-negotiable.

Ready for Unmatched Wear Performance?

Whether you’re battling abrasive ores, heavy impacts on construction sites, or the constant wear of material transport, Truecasteng has the precision casting expertise and durable wear solutions you need.

Contact Truecasteng today to discuss your specific requirements. Let us craft the durable, high-performance components that keep your critical equipment running longer and stronger.