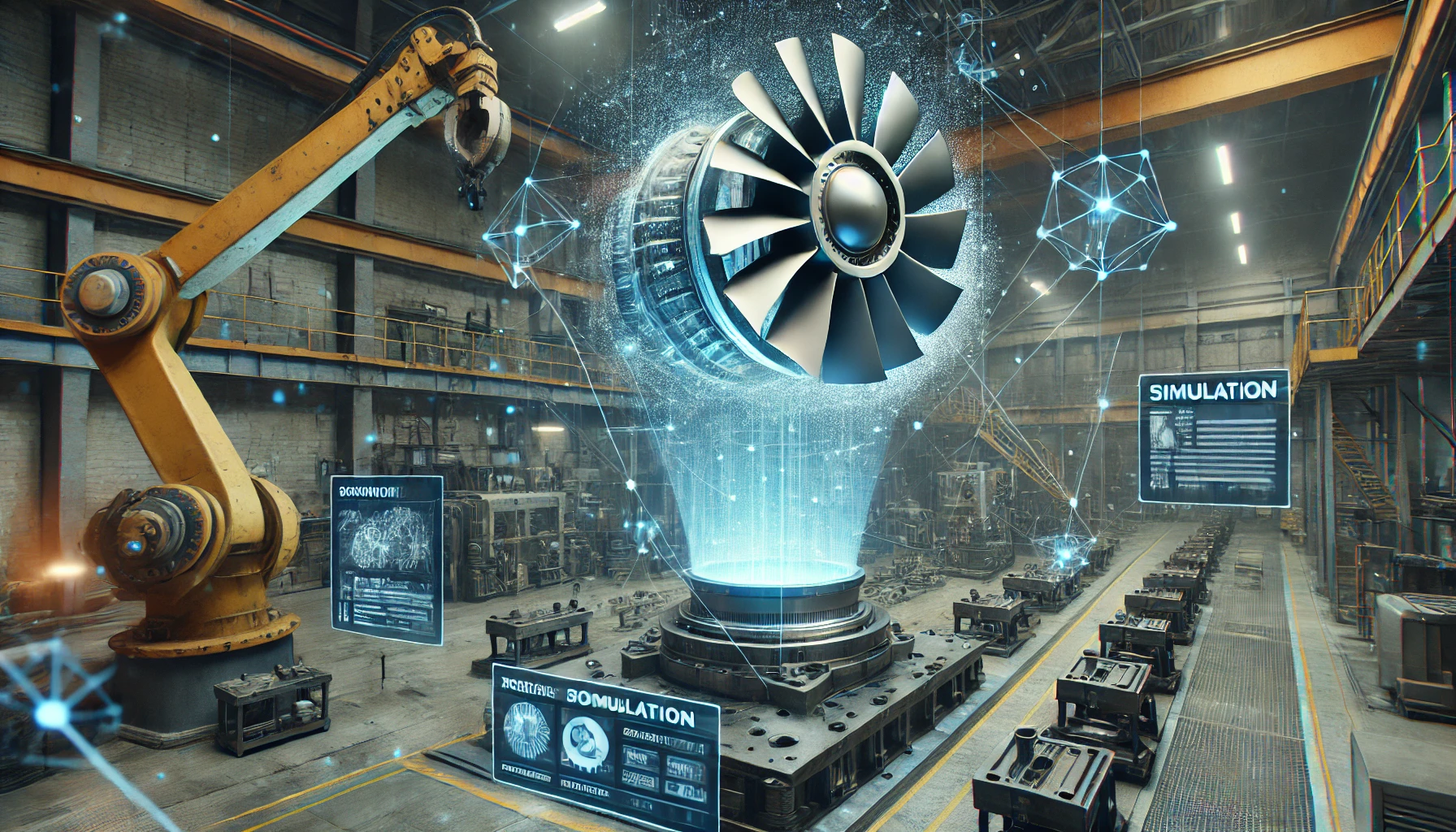

Digital Twins in Precision Casting: Bridging Virtual and Physical Manufacturing

As Industry 4.0 reshapes manufacturing, precision casting is entering a new era where every physical component has a virtual counterpart. Digital twin technology – the practice of creating dynamic digital replicas of physical systems – is revolutionizing how foundries design, optimize, and maintain casting processes.

Why Digital Twins Matter

Digital twins solve two critical challenges in precision casting:

- Predictive Process Control:

- Simulate metal flow, solidification, and stress distribution in real-time

- Predict and prevent defects like shrinkage porosity with 95% accuracy

- Lifecycle Management:

- Track component performance from casting to end-of-life

- Enable predictive maintenance for industrial castings

Key Applications

1. Virtual Process Optimization

- Test 200+ gating system designs in 48 hours (vs. 6 weeks physically)

- Reduce scrap rates by 30-45% through simulated thermal analysis

2. Smart Quality Assurance

- Compare 3D-scanned castings against digital twins using AI

- Achieve 0.02mm repeatability across production batches

3. Customer Collaboration

- Share interactive twins with clients for real-time design feedback

- Accelerate approval cycles by 70%

Case Study: Aerospace Innovation

A Tier-1 aerospace supplier implemented our digital twin solution to:

- Cut lead time for complex fuel nozzle castings from 14 to 5 weeks

- Reduce X-ray inspection costs by $120,000/year

- Achieve 100% first-article approval rate

The Technology Stack

Our platform integrates:

- IoT Sensors: 500+ data points collected per casting cycle

- Multiphysics Simulation: ANSYS-powered fluid dynamics modeling

- Blockchain Traceability: Immutable quality records meeting AS6496 standards

Future Outlook

With 5G and edge computing, next-gen twins will:

- Provide real-time augmented reality (AR) guidance for technicians

- Automatically adjust furnace parameters via machine learning

- Enable mass customization of cast components

At Truecasteng, we’re pioneering Industry 4.0-ready casting solutions. Our digital twin services are compliant with ISO 23247 and fully integrable with your PLM systems.

Ready to See Your Castings in a New Dimension?

Schedule a demo to explore how digital twins can transform your foundry operations.