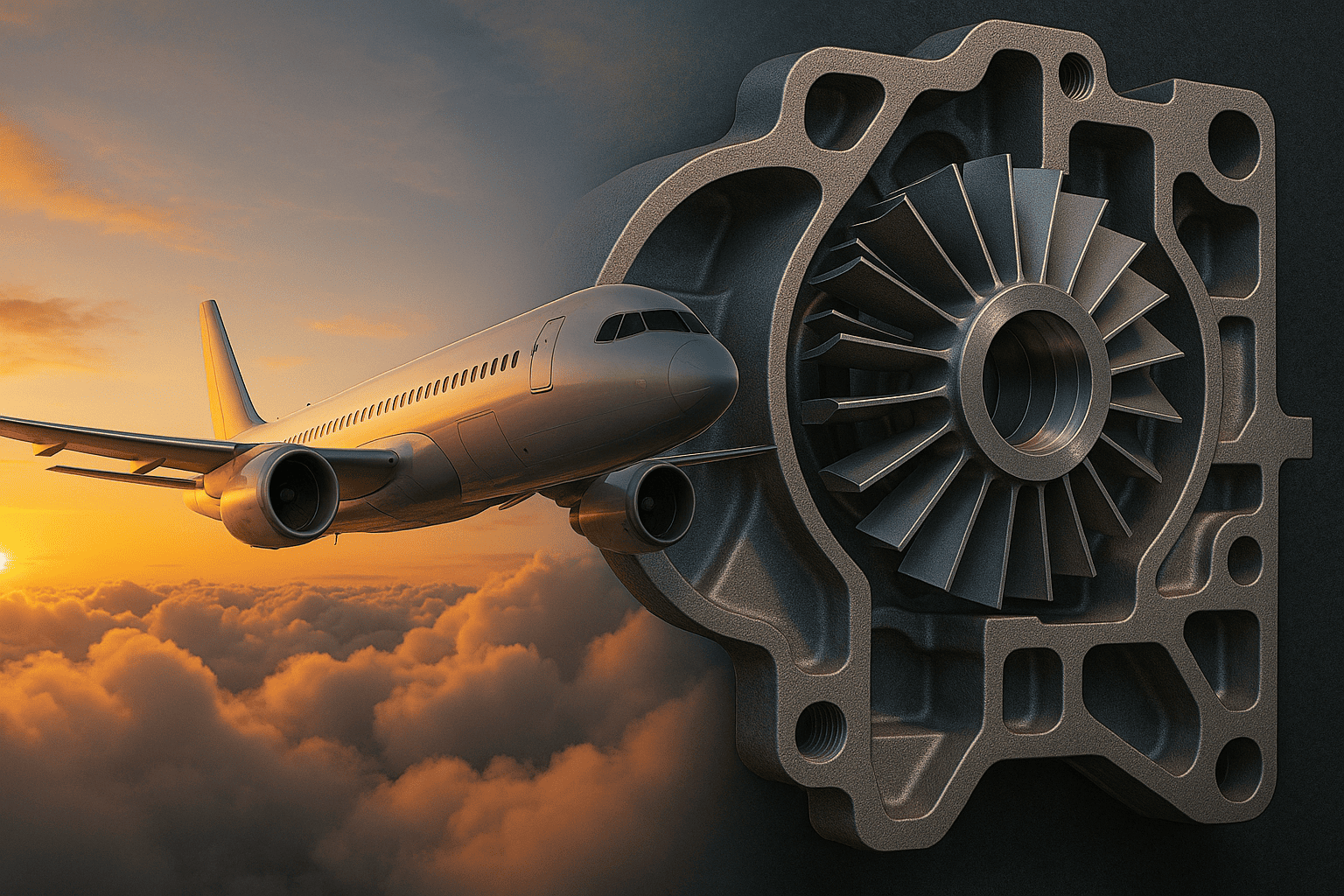

Precision Casting for Aerospace Components: Elevating Performance to New Heights

The aerospace industry represents the pinnacle of engineering challenges, where every gram counts and failure is never an option. In this demanding environment, precision casting has become the manufacturing backbone for components that must perform flawlessly under extreme conditions while meeting exacting weight targets. From commercial airliners to spacecraft, the technology enables designs that push the boundaries of what’s possible in flight.

Aerospace components face a unique combination of stresses that test materials to their limits. Turbine blades operate at temperatures exceeding the melting point of their base alloys. Landing gear must absorb tremendous impact forces without deformation. Structural elements require perfect balance between strength and weight. Traditional manufacturing methods struggle to meet all these demands simultaneously – forgings lack complexity, machined parts waste material, and assemblies introduce potential failure points. Precision casting overcomes these limitations by creating near-net-shape components with optimized material properties throughout.

The material science behind aerospace castings reads like something from advanced laboratories. Single-crystal nickel superalloys grow with carefully controlled crystalline structures that eliminate weak grain boundaries. Titanium aluminide components achieve high-temperature strength at nearly half the weight of conventional alloys. Perhaps most remarkably, modern foundries can engineer different properties within a single casting – creating parts with cooling-channeled surfaces that withstand 1,500°C gas flows while maintaining ductile cores that resist fatigue cracking. These material marvels are achieved through vacuum casting processes and precisely controlled solidification that would be impossible with other production methods.

Geometric capabilities make precision casting equally transformative for aerospace applications. The complex internal cooling channels in turbine blades – some no wider than a human hair – can only be produced through investment casting. Lightweight structural brackets with organic, weight-optimized shapes outperform their machined counterparts. Fuel system components combine multiple functions into single castings, reducing potential leak points. Additive manufacturing integration now allows for even more radical designs, such as turbine blades with fractal cooling networks or satellite components with mathematically perfect lattice structures.

The performance benefits are substantial. Aircraft manufacturers report:

• 20-30% weight reduction in critical components

• 2-3X longer service life for turbine components

• 15-20% improvement in fuel efficiency from optimized designs

These advantages multiply across an aircraft’s thousands of components, making precision casting a strategic differentiator in the highly competitive aerospace market.

Looking ahead, the technology continues to evolve in ways that will redefine aerospace possibilities. Smart castings with embedded sensors will provide real-time structural health monitoring. Self-healing materials may automatically repair minor damage during flight. New alloys promise even greater temperature resistance for next-generation engines.

For an industry where performance and safety margins are measured in fractions of a percent, precision casting provides more than just components – it delivers the material advantages that make modern flight possible. Truecasteng has been at the forefront of this aerospace revolution, with our castings flying in some of the world’s most advanced aircraft. When failure isn’t an option and every gram matters, aerospace engineers turn to precision casting – not just as a manufacturing process, but as an enabling technology for the future of flight.