Precision Casting for Marine & Offshore Applications: Engineering Solutions for the Harsh Ocean Environment

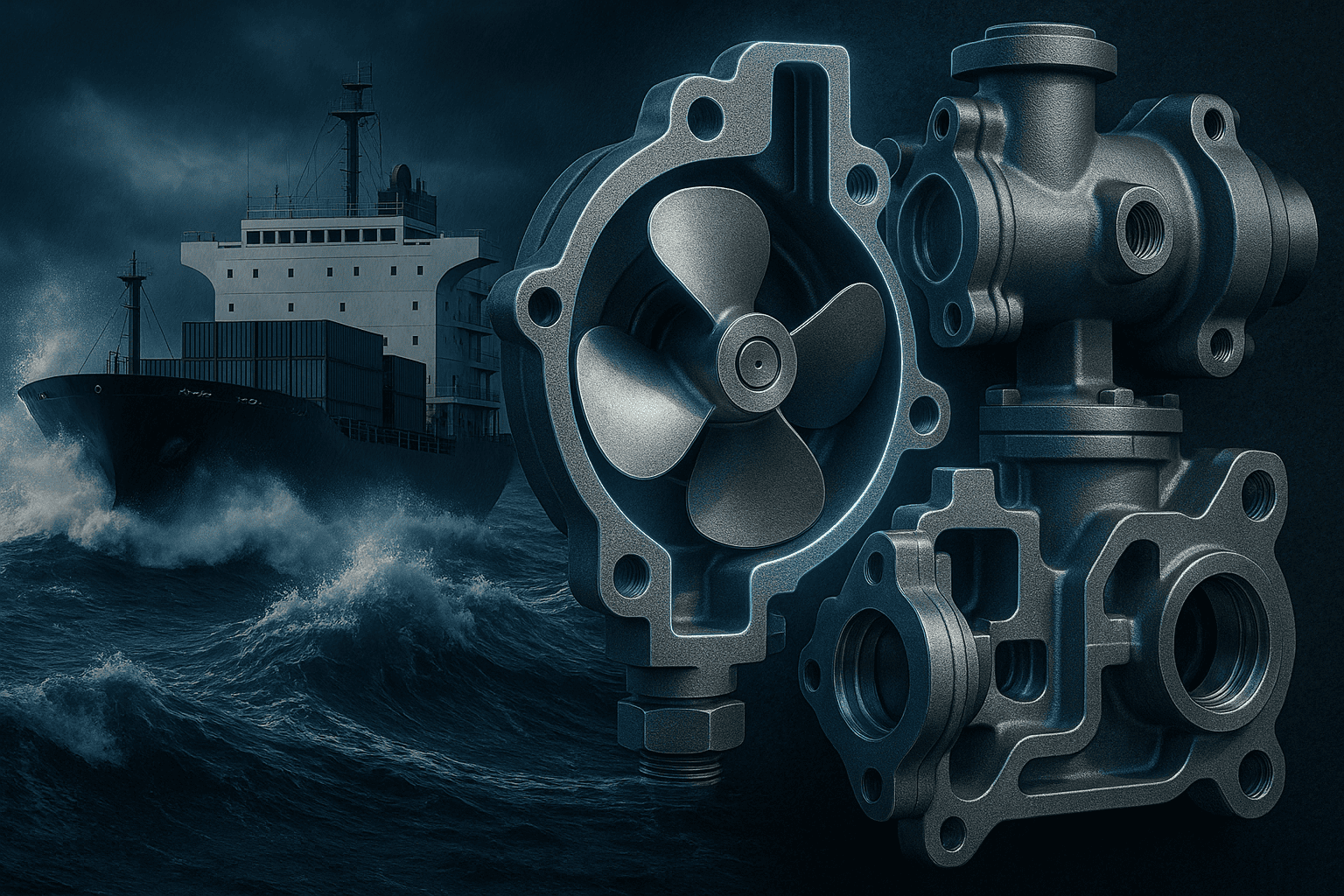

The marine industry presents one of the most punishing environments for engineered components, where saltwater corrosion, constant vibration, and extreme pressures combine to test the limits of material science. In this challenging arena, precision casting has emerged as the manufacturing method of choice for critical components that simply cannot fail at sea. From massive ship propellers to delicate valve systems, the technology delivers unparalleled reliability where traditional manufacturing methods fall short.

Marine components face a perfect storm of destructive forces. Saltwater accelerates corrosion rates by 10-100 times compared to freshwater environments. Biofouling organisms aggressively attack surfaces. Cyclic loading from waves creates metal fatigue. And in deepwater applications, pressures can exceed 5,000 psi. Conventional fabrication techniques struggle with these conditions – welded joints corrode at the heat-affected zones, assembled components work loose from vibration, and homogeneous materials can’t provide the varied properties needed throughout a single part. Precision casting solves these problems through three fundamental advantages: material integrity, geometric freedom, and design-specific property engineering.

The metallurgical innovations in marine castings are particularly remarkable. Advanced bronze alloys like nickel-aluminum bronze (NAB) offer exceptional corrosion resistance while maintaining high strength. Duplex stainless steels provide chloride resistance for pump components. Most impressively, modern foundries can now engineer material properties that vary within a single casting – creating parts with corrosion-resistant exteriors, high-strength cores, and wear-resistant bearing surfaces all in one piece. This is achieved through precise control of cooling rates and advanced heat treatment protocols that would be impossible with other manufacturing methods.

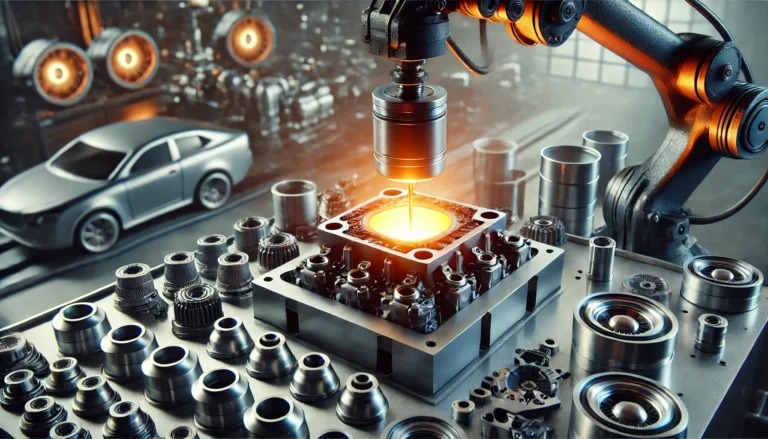

Geometric capabilities make precision casting equally valuable for marine applications. The complex curved shapes of propeller blades achieve optimal hydrodynamic efficiency when cast as single pieces. Pump volutes with gradually expanding channels maximize flow while minimizing cavitation. Valve bodies can incorporate internal passages that would require multiple assembled parts in other manufacturing approaches. Recent advances in 3D printed sand molds have expanded these possibilities further, allowing for cooling channels that follow stress lines, honeycomb reinforcement structures, and other optimized geometries that significantly enhance performance and longevity.

The economic case for marine precision castings is compelling. Shipping companies report:

• 50-70% longer service intervals for cast propellers versus fabricated alternatives

• 30-40% reduction in drydock time due to more reliable components

• 15-25% fuel savings from hydrodynamically optimized shapes

These benefits multiply across a vessel’s many systems, making precision casting a strategic advantage for shipbuilders and operators alike.

Looking ahead, the technology continues to evolve in ways particularly suited to maritime challenges. Smart castings with embedded corrosion sensors will provide early warnings of material degradation. New biofouling-resistant surface treatments are being developed that are cast directly into components. Digital twin technology allows virtual testing of designs under simulated ocean conditions before production begins.

For an industry where equipment failures can endanger lives, cause environmental disasters, and result in millions in losses, precision casting provides more than just durable parts – it delivers engineered reliability where compromise isn’t an option. [Your Company Name] has been at the forefront of this marine revolution, with our components sailing every ocean and operating in the most challenging offshore environments. When failure isn’t an option, the world’s marine industry turns to precision casting – not just as a manufacturing method, but as a guarantee of performance where it matters most.