Precision Casting: The Backbone of Modern Manufacturing

In today’s fast-paced manufacturing world, precision and efficiency are the keys to staying ahead of the competition. One process that has become indispensable in producing high-quality components for a variety of industries is precision casting, also known as investment casting. From aerospace to medical devices, automotive to energy, this technique plays a vital role in shaping the parts that power our world.

In this blog post, we’ll explore what precision casting is, how it works, why it’s essential for OEMs, and the advantages it offers in a global supply chain.

What Is Precision Casting?

Precision casting is a metal-forming process that creates complex and highly detailed metal parts by using a wax pattern that is coated with a ceramic shell. Once the wax is melted and drained, molten metal is poured into the mold to form the desired component.

This process is known for producing parts with excellent dimensional accuracy, smooth surface finishes, and minimal need for further machining. It allows manufacturers to cast near-net-shape parts, reducing material waste and production time.

How the Precision Casting Process Works

The precision casting process typically includes the following steps:

- Wax Pattern Creation – A wax replica of the final part is created using a metal die.

- Assembly – Multiple wax patterns may be assembled into a “tree” to allow for multiple parts to be cast at once.

- Shell Building – The wax tree is repeatedly dipped in a ceramic slurry and coated with fine sand to form a hard ceramic shell.

- Wax Removal – The shell is heated, melting and draining the wax to create a hollow mold.

- Casting – Molten metal is poured into the pre-heated ceramic mold.

- Cooling and Shell Removal – After cooling, the ceramic shell is broken away to reveal the cast part.

- Finishing – The castings are cut from the tree, cleaned, and finished as required (grinding, machining, heat treatment, etc.).

Applications of Precision Casting

Precision casting is widely used across various industries due to its flexibility and reliability:

- Aerospace: Turbine blades, engine components, structural parts.

- Automotive: Exhaust manifolds, brackets, transmission parts.

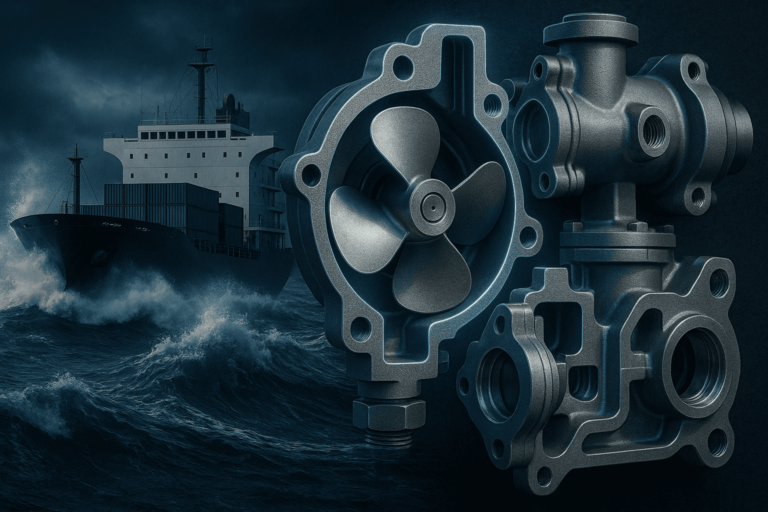

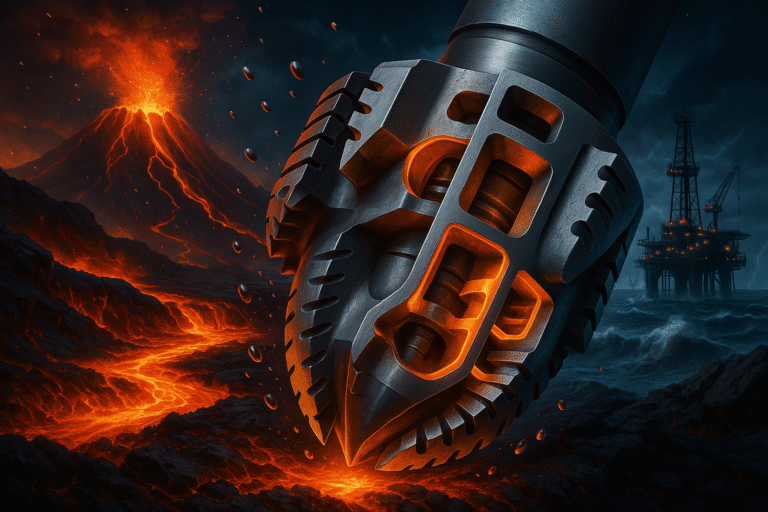

- Oil & Gas: Valve bodies, pump components, impellers.

- Medical: Surgical tools, orthopedic implants.

- Industrial Machinery: Gear housings, levers, and custom fittings.

Its ability to create complex shapes in high-performance alloys makes it ideal for critical applications where failure is not an option.

Why OEMs Choose Precision Casting

OEMs (Original Equipment Manufacturers) often select precision casting for its distinct advantages:

- Design Freedom: The process supports intricate designs that are difficult or impossible to achieve with traditional machining.

- Tight Tolerances: High dimensional accuracy reduces the need for secondary operations.

- Material Variety: Compatible with a wide range of ferrous and non-ferrous alloys, including stainless steel, carbon steel, and aluminum.

- Cost Efficiency: For complex parts, investment casting often results in lower total production costs due to reduced machining and assembly.

Precision Casting and Global Trade

In the global supply chain, precision casting suppliers must meet demanding international standards. At Truecasteng, we specialize in exporting high-quality cast components to OEMs across North America, Europe, and beyond. Our team leverages decades of experience, advanced inspection equipment, and a commitment to quality control to ensure every part meets or exceeds customer expectations.

We understand that overseas buyers value consistency, clear communication, and on-time delivery — and that’s exactly what we deliver.

Conclusion

Precision casting continues to be a pillar of modern manufacturing. Its unmatched combination of design flexibility, accuracy, and strength makes it ideal for industries that demand top-tier performance and reliability.

Whether you are an OEM seeking a trusted supplier or a manufacturer exploring new production methods, investment casting is a solution worth considering. At Truecasteng, we’re proud to offer precision casting services tailored to the needs of global customers — with quality, reliability, and service at the heart of everything we do.