The Backbone of Modern Construction Machinery

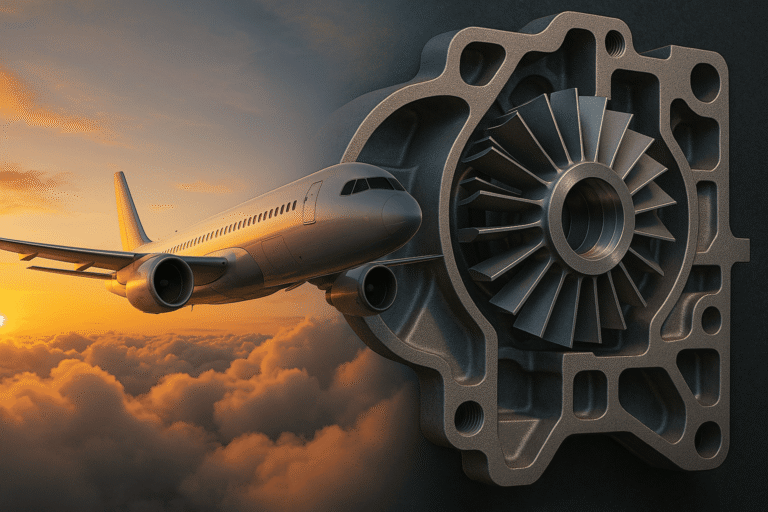

Beneath the roaring engines and towering frames of today’s construction equipment lies an unsung hero – precision casting. This centuries-old craft has evolved into a sophisticated manufacturing solution that determines the very lifespan and performance of our earthmoving giants.

The construction sector presents some of manufacturing’s most brutal challenges. Excavator teeth gnaw through abrasive soils, bulldozer blades push against unyielding terrain, and crane components bear loads that would deform lesser materials. Traditional fabrication methods often fall short, leading to premature failures that cost millions in downtime. This is where precision casting steps in, not just as an alternative, but as a transformative approach to heavy equipment manufacturing.

What sets precision casting apart is its unique marriage of material science and engineering artistry. Our foundries work with specialized alloys like high-chrome white iron and nickel-chrome steels that are literally designed to thrive under punishment. These aren’t just strong materials – they’re smart ones. The metallurgical composition varies throughout each casting, creating components that are hard where they need to resist wear but tough where they must absorb impacts. A single bucket tooth might incorporate three different material zones, each meticulously engineered through controlled cooling processes.

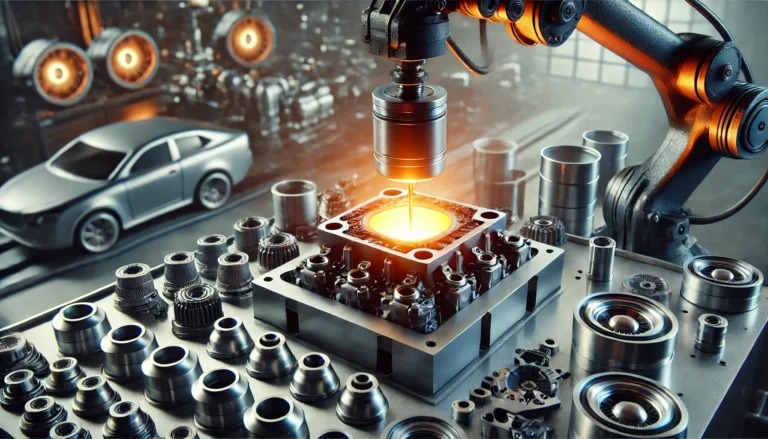

The advantages manifest most clearly in real-world performance. Consider the undercarriage components of a 50-ton excavator. Traditional fabricated track links might last six months in abrasive conditions. Our precision-cast versions routinely exceed 18 months of service while maintaining tighter tolerances. This isn’t just about longevity – it’s about maintaining precision over time. The difference comes down to microstructure. Where welded assemblies develop stress concentrations, our monolithic castings distribute loads evenly throughout their crystalline structure.

Hydraulic systems present another compelling case. Modern construction equipment relies on increasingly complex fluid pathways that would be impossible to machine from solid blocks. Our casting techniques can create intricate internal geometries that optimize flow dynamics while maintaining structural integrity. One recent development – a single-cast hydraulic manifold for a wheel loader – reduced potential leak points from 28 in the traditional design to just 3, while improving flow efficiency by 22%.

Sustainability has become an unexpected strength of precision casting. The process naturally lends itself to material efficiency, with near-net-shape production minimizing waste. Our closed-loop recycling systems recover and reuse over 90% of materials, while energy recovery installations capture waste heat from pouring operations. The result is a manufacturing process that’s not just tougher, but cleaner than alternatives.

Looking ahead, we’re integrating digital technologies that will further revolutionize the field. Embedded sensors in cast components will provide real-time wear data, while machine learning algorithms optimize pouring parameters for each unique geometry. The future construction site may well be populated by machines whose bones remember every stress they’ve endured – and tell their operators when to service them.

For equipment manufacturers, the implications are profound. Precision casting isn’t just changing how we make parts – it’s changing what machines can do. When components last longer, perform better, and fail less often, the entire economics of construction operations shift. The machines become not just tools, but reliable partners in building our world.

This is the quiet revolution happening in foundries around the world – one precisely cast component at a time. The next generation of construction equipment won’t just be stronger or more durable. It will be fundamentally different because of what precision casting makes possible. And that transformation is already underway.

Truecasteng stands at the forefront of this revolution, combining ancient metallurgical wisdom with cutting-edge technology. Our engineering team welcomes the opportunity to discuss how precision casting can elevate your equipment’s performance – because in the world of construction machinery, the future isn’t just being built. It’s being cast.